When it comes to building the Adirondack chairs nothing is left out. From the shape, design, contour, and ergonomics everything is included within the designs. Each piece of lumber is hand-picked, sorted and milled by me or one of my craftsmen. A lot of my orders come from people that have been at someone’s house and have actually seen or sat in one of our chairs. This is what is called referral business, the best kind of business there is.

The backs of the chairs start out as 1" x 6" lumber. Many of the chair parts start out as 1" x 6" lumber and are ripped to get the thinner slats that you see. After that they are put through a router, then countersunk and individually sanded. The number of screws that are in each chair varies according to which chairs is ordered. Fish chairs have roughly 70 to 90 screws in each back assembly. The backs arrive to you in one piece and only a couple bolts are used to assemble them. Detailed instructions are in the video on the assembly page of this website.

The bottoms of my chairs are made from 2 x 6" lumber. This gives you a full 1 1/2"on all ground contact. All the bottoms are made from the same size lumber. These 2 x 6's are pressure-treated and with complete ground contact are rated for 20 year life. Although I don't offer untreated lumber as a choice, orders for Cypress and Cedar are welcome.

The hardware used to assemble the chairs comes standard, galvanized, and stainless-steel is available with an up charge. 95% of the screws are installed when you receive your chair and in all reality there are only 8 screws and 8 bolts which need to be installed by you. Most of the slats on the chairs have 4 to 6 screws to restrict cupping of the wood as it dries.

Being that the chairs are made to order the lumber is bought when an order is placed and paid for. This gives the purchaser the opportunity to have the lumber arrived to them in as much of an uncured state as possible. The color that the chair starts to take upon drying will depend on your demographics and elements. Some chairs change to a dark gray and some areas bring out a much lighter gray as the chair ages. Some tend to keep their auburn color and change to a darker brown from there.

Although it is recommended that you have the chairs for at least a month before painting or staining, you’re welcome to paint or stain them at any time. I don't make it a habit of painting the chairs as sometimes the color that comes out may not be the exact wish of the buyer, because of this I leave the painting up to you.

The chairs are sanded and ready to paint when you receive them. Using a semi-solid color stain or solid color stain will leave the wood grain visible. A latex or enamel paint will cover the chair completely and no wood-grain or very little wood-grain will show through.

Once again, thank you for coming by.

FishChairs.com

Frequently Asked Questions

Pressure-treated Southern yellow pine. At this time, this is your only option.

Chair Dimensions: 36" Deep x 36" Wide x 39" High

Seat Inset: 18" Deep x 24" Wide

Seat Height: 15 inches

Weight Capacity: 350 lbs

Wood Type: Southern Yellow Pine

The chairs are made from full 3/4" thick wood, and the legs on our chairs are made from stock 2" x 6" lumber. This makes the true thickness of our legs to be a full 1 and 1/2 inches thick. Comparable to the other adirondack chairs online, there is no comparison.

Unless otherwise requested, galvanized coated hardware is used. As an up-charge stainless steel hardware is available.

The chairs are built to order. You can expect delivery within 1 week. Larger orders will take longer.

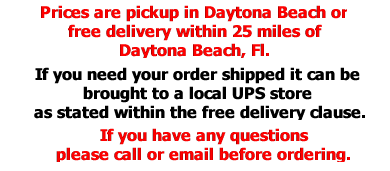

Delivery is free within 25 miles of Daytona Beach, Florida. How many chairs you order, greatly affects how they will be delivered. If you live outside our delivery area, we can help you arrange shipping to your destination. Give us a call @ 315-601-4967, we'll be happy to help you make arrangements.